Starting from a drawing (2D or 3D) or a sample (reverse engineering), we help our customer in finding technical solutions in order to reduce production time and costs and to improve the performance of their products.

Relying on over forty years of experience, we are able offer the best solutions according to the specific application, from the selection of the raw material to the processing technology to be used.

After the analysis and collection of customer requests, in order to get to the best possible solution in terms of quality, time and cost, the first fundamental step is the design of the mold.

Thanks to our cooperation with various domestic and international specialized workshops, selected according to the type of application chosen, we design and produce molds for plastic materials, guaranteeing the customer the highest quality and a durable operation, in line with the required qualities.

We offer the possibility to create prototypes through 3D printing or traditional molding, using low-cost pilot molds, in order to identify potential problems or to evaluate possible changes to the project.

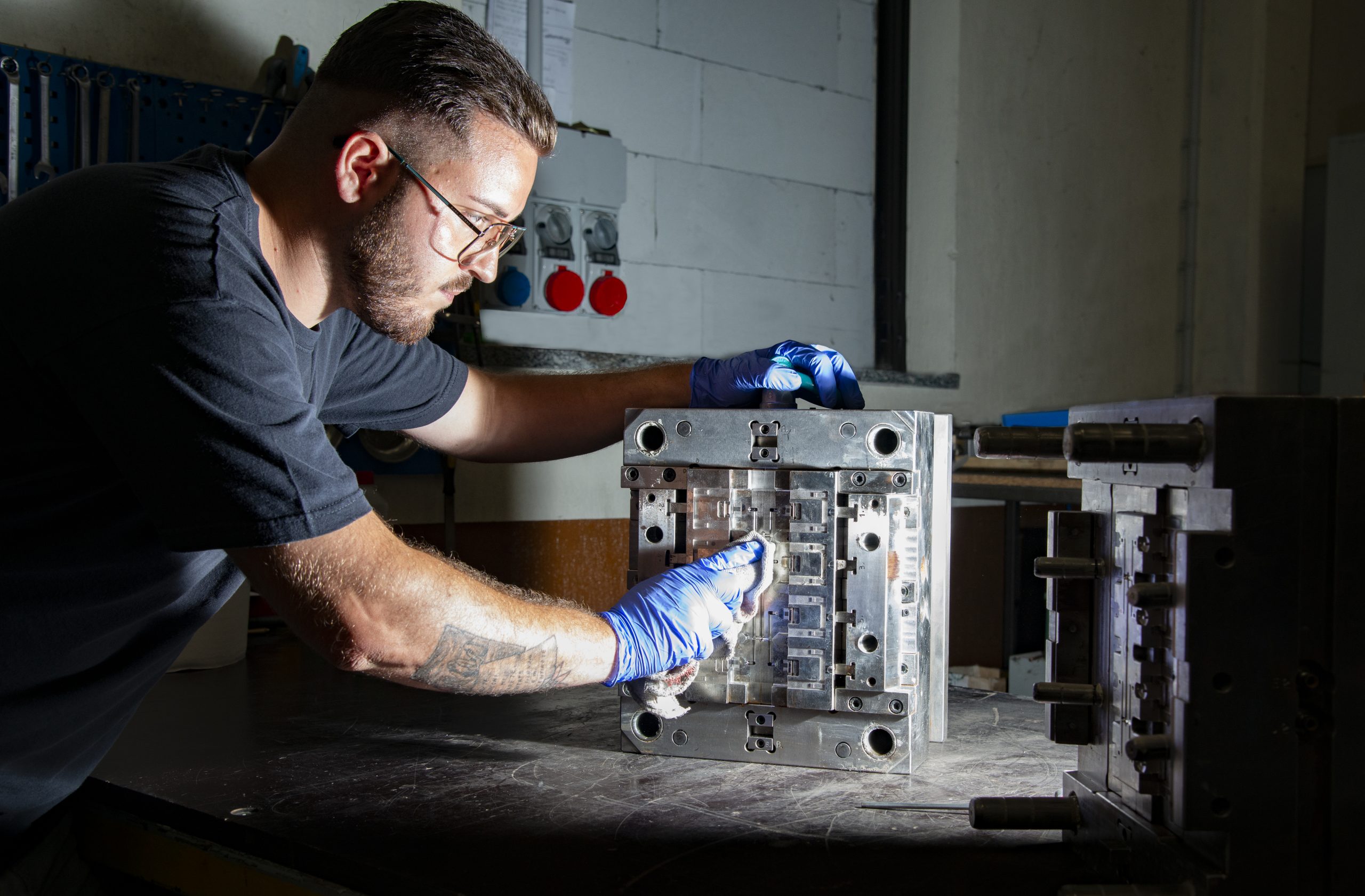

We also dedicated an area to the versioning, maintenance and cleaning of the mold in order to minimize the sampling and maintenance times.